Manufacturing

Key Reasons for Manufacturing Companies to Adopt Solar PV

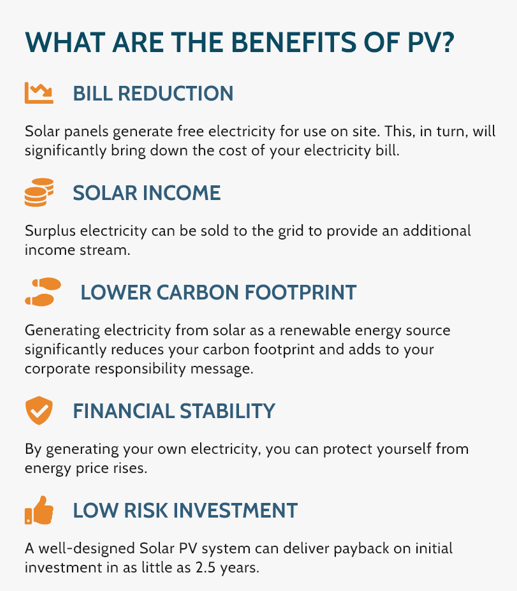

- Maximized On-Site Utilization: Most generated electricity can be used in manufacturing processes, ensuring significant cost savings.

- Quick Financial Payback: Typically, solar PV systems pay back in 2-4 years, providing a fast return on investment.

- Long Product Warranties: Ensures reliability and low maintenance over the system’s lifespan.

- Lower Electricity Bills: Reduces dependence on expensive grid electricity.

- Environmental Benefits: Decreases carbon footprint and supports sustainability goals.

- Reduced Carbot Emissionse: Improves scope 1 and 2 for you and scope 3 emissions for your clients.

- Space Efficiency: High efficiency without impacting valuable manufacturing space.

Generate electricity with Solar PV

Manufacturing companies are ideal candidates for Solar PV systems because they can utilise nearly all of the electricity generated on-site, maximizing electricity cost savings. Solar PV provides very low-risk electricity generation with quick financial paybacks, typically between 2 to 4 years, and offers very long product warranties. Generating your own electricity is an excellent way to lower electricity bills, reduce your carbon footprint, and promote a positive environmental message.

The PV panels are efficient enough to produce almost 200W/m², and unlike other on-site generating plants, they have no space impact on the internals of the building itself.

Minimum requirements for Solar PV

These indicators will ensure your PV system provides a good financial return:

- 3 phase supply to the building

- Roof area > 250m2

- Total electricity bill of over £40,000/yr

- Electrical cost > 20p/kWh

If you meet these criteria then call us today and we will help you realise the financial gains available from a PV installation.

Heating systems for Manufacturing Sites

Myriad have been installing low carbon commercial and industrial heating systems for over 20 years. We know that heating huge spaces like warehouses and workshops can be extremely costly. This cost is even higher due to the industry’s reliance on heating oil, LPG or electric energy.

We’ve found that using a sustainable type of energy can vastly reduce the cost of your fuel/heating bills, whilst also reducing your site(s) carbon emissions.

A Biomass Boiler is a good solution for heating warehouses and workshops as it provides high grade heat, unlike Heat pumps which work better at lower temperatures.

Biomass boilers can provide the same output capabilities (temperature, pressure) as their polluting alternatives, providing you with a wide variety of end-processes. They can provide Hot air, Low Temp Hot Water (<100degC), Medium Temp Hot water (>110degC) and Steam for any process you may have.

We have worked on many warehouse heating schemes - using straightforward fan coil heaters directly in the work space and also more complex solutions, such as providing heat for the wider site including offices and other buildings via a district heating scheme.