Gas CHP

Gas Combined Heat & Power CHP Products

Generate heat and power simultaneously and reduce carbon emissions by up to 30%. Gas CHP systems are highly efficientthis is your opportunity to reduce energy costs and improve the environmental performance of your business or organisation.

Myriad can design, supply and maintain your CHP system.

Biogas CHP Module

Biogas CHP Module. Heat and electrical power generated from biogas.

Wolf BHKW units have the same essential structure over the full range of powers out puts: a frame constructed of steel sections forms the heat exchanging unit with the connections for the heating supply and return lines, exhaust and fuel.

The unit comprises a plate heat exchanger that takes heat from the engine's cooling water, a shell and tube heat exchanger that exchanges heat with the exhaust, and a flue gas cleaning unit.

A combined heat and power unit can achieve an efficiency of about 90%, meaning that 90% of the primary energy is converted into electricity and heat. If the radiated heat can be included, the efficiency can even reach about 95%. The efficiency of a conventional power station is between 30 and 40%. The advantages are clear.

*Efficiency figures are due to variations in measurements, fluctuating conditions and variations in the fuel quality of a tolerance of up to 5%.

Individual system solutions with integration of

- heating, air handling and ventilation

- thermal oil applications

- steam applications

- adsorbtion and absorbtion cooling applications

- Optional emergency power supply and stand-alone solutions

Natural gas, sewage gas, LPG and biogas are likely sources of primary energy. The combustion engine, a gas-burning four stroke engine, drives a generator. The generator converts part of the energy used into electrical power. The electricity is used in the consumer network or is given directly to the power supply company.

- Electrical Power

- 10 - 2,000 kWe

- Thermal Power

- 15 - 2,000 kWt

- Efficiencies

- Up to 90%

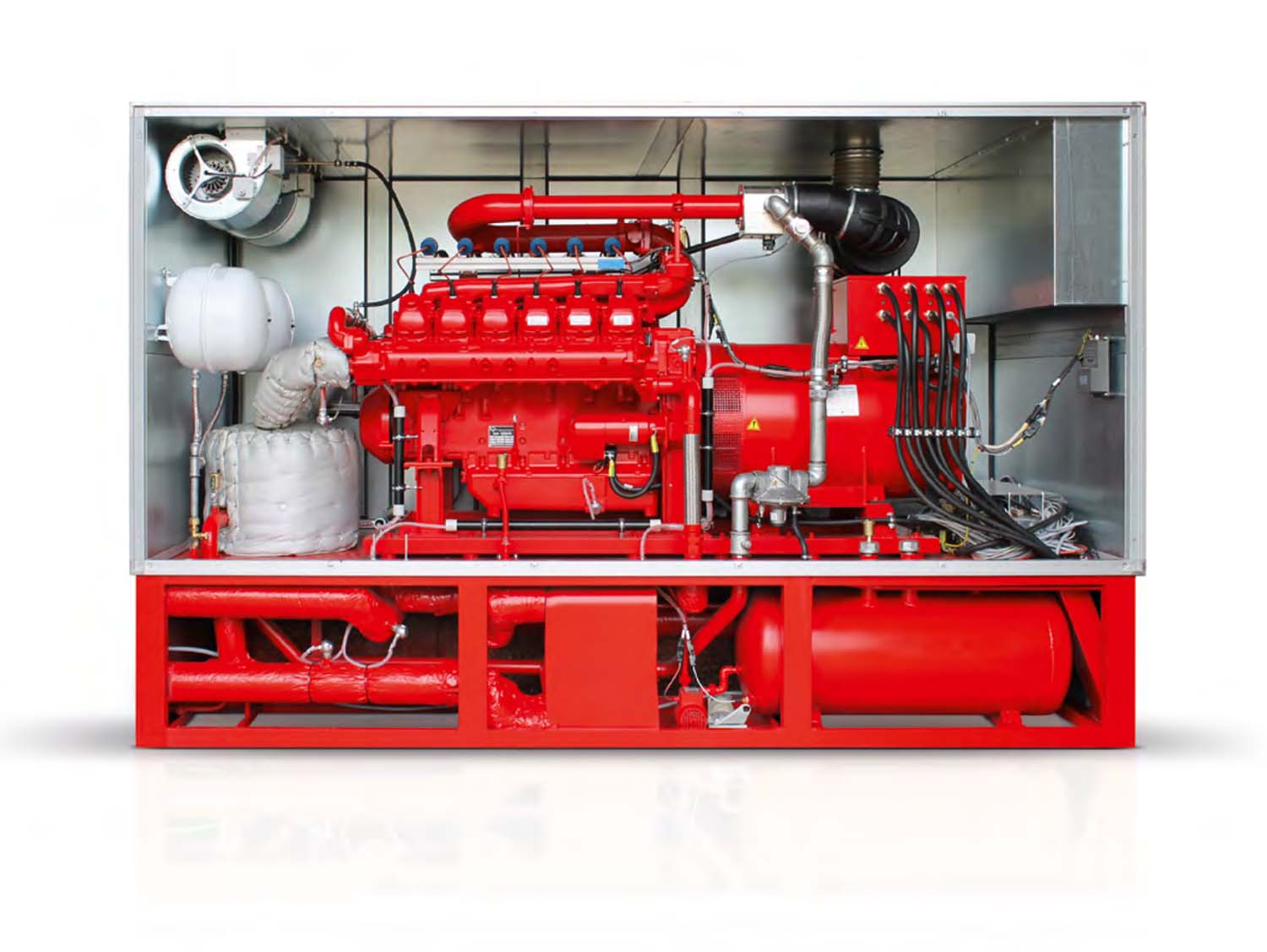

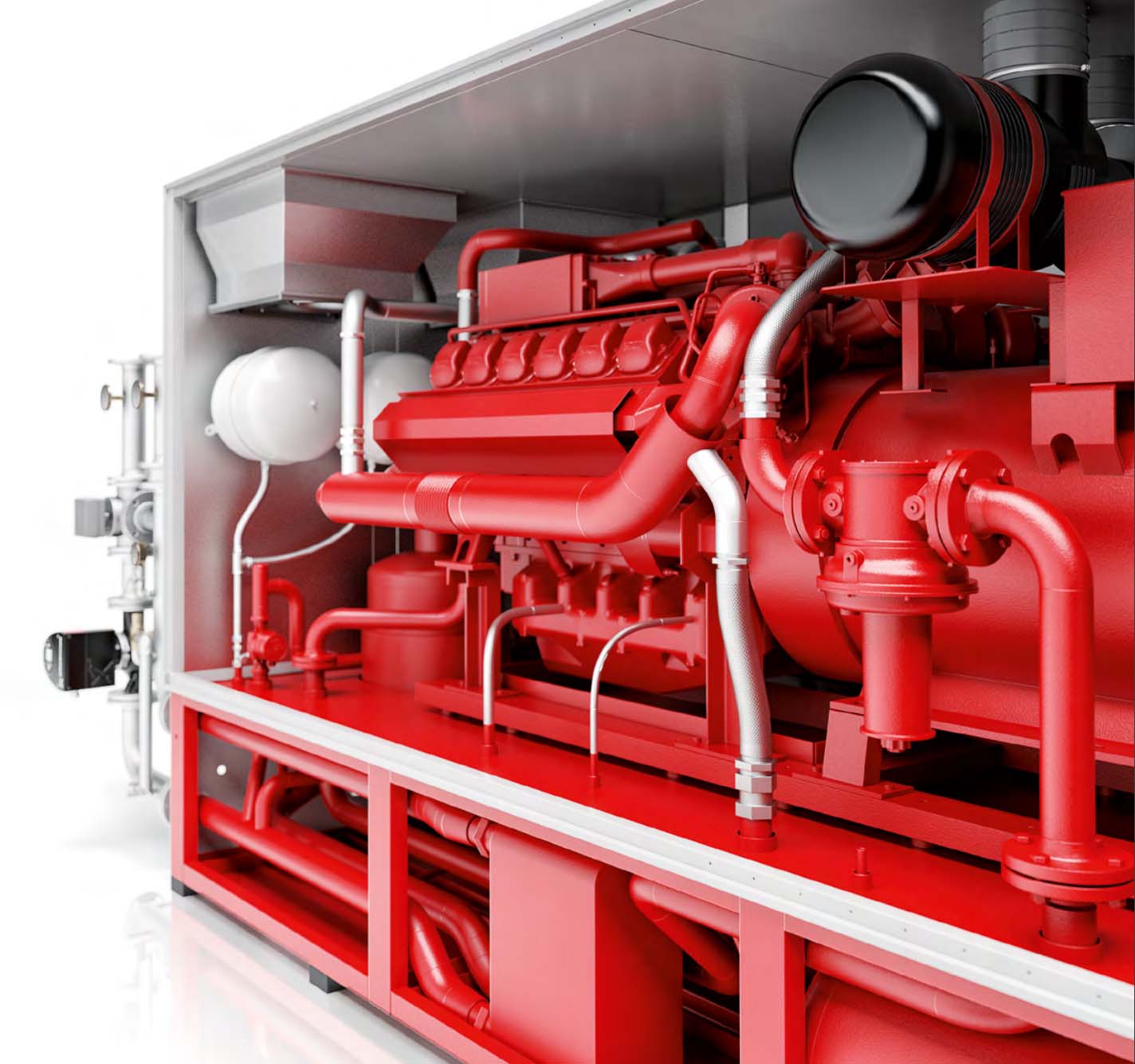

Natural Gas CHP Module

Wolf BHKW units have the same essential structure over the full range of powers out puts: a frame constructed of steel sections forms the heat exchanging unit with the connections for the heating supply and return lines, exhaust and fuel.

The unit comprises a plate heat exchanger that takes heat from the engine's cooling water, a shell and tube heat exchanger that exchanges heat with the exhaust, and a flue gas cleaning unit.

A combined heat and power unit can achieve an efficiency of about 90%, meaning that 90% of the primary energy is converted into electricity and heat. If the radiated heat can be included, the efficiency can even reach about 95%. The efficiency of a conventional power station is between 30 and 40%. The advantages are clear.

*Efficiency figures are due to variations in measurements, fluctuating conditions and variations in the fuel quality of a tolerance of up to 5%.

Individual system solutions with integration of

- heating, air handling and ventilation

- thermal oil applications

- steam applications

- adsorption and absorption cooling applications

- Optional emergency power supply and stand-alone solutions

Natural gas, sewage gas, LPG and biogas are likely sources of primary energy. The combustion engine, a gas-burning four stroke engine, drives a generator. The generator converts part of the energy used into electrical power. The electricity is used in the consumer network or is given directly to the power supply company.

- Electrical Power

- 20 - 2,000 kWe

- Thermal Power

- 22 - 1,970 kWt

- Efficiencies

- Up to 90%

LPG Gas CHP Module

Wolf BHKW units have the same essential structure over the full range of powers out puts: a frame constructed of steel sections forms the heat exchanging unit with the connections for the heating supply and return lines, exhaust and fuel.

The unit comprises a plate heat exchanger that takes heat from the engine's cooling water, a shell and tube heat exchanger that exchanges heat with the exhaust, and a flue gas cleaning unit.

A combined heat and power unit can achieve an efficiency of about 90%, meaning that 90% of the primary energy is converted into electricity and heat. If the radiated heat can be included, the efficiency can even reach about 95%. The efficiency of a conventional power station is between 30 and 40%. The advantages are clear.

*Efficiency figures are due to variations in measurements, fluctuating conditions and variations in the fuel quality of a tolerance of up to 5%.

Individual system solutions with integration of

- heating, air handling and ventilation

- thermal oil applications

- steam applications

- adsorbtion and absorbtion cooling applications

- Optional emergency power supply and stand-alone solutions

Natural gas, sewage gas, LPG and biogas are likely sources of primary energy. The combustion engine, a gas-burning four stroke engine, drives a generator. The generator converts part of the energy used into electrical power. The electricity is used in the consumer network or is given directly to the power supply company.

- Electrical Power

- 12 - 2,000 kWe

- Thermal Power

- 18 - 1,970 kWt

- Efficiencies

- Up to 90%