Waste Wood Boilers & Processing Plant

Waste Wood Boilers & Processing Plant

Get Smart About Waste

Paying to dispose of your wood waste is an added cost you don’t need. The impact it has on landfill is also something to consider.

Instead, why not invest in a biomass boiler system that can convert this waste on-site into efficient, clean energy, enabling you to put the phone down on those skip hire companies.

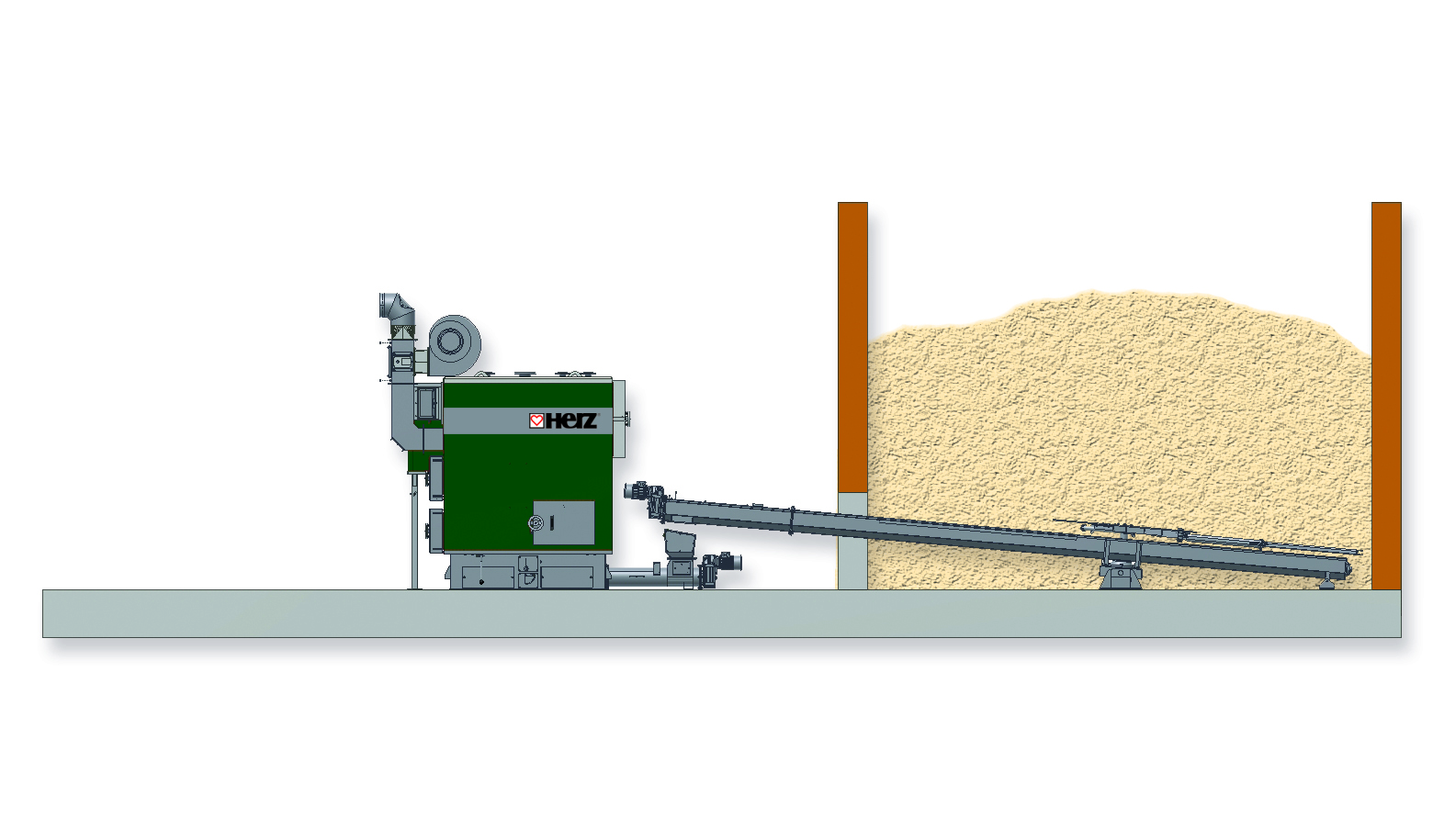

Waste Wood Storage and Transport Systems

Industrial boilers are designed to run continuously so it is very important to note that the fuel storage solution for these boilers needs to be much larger as the high duty boilers will burn the material at a very fast rate. So, the storage and transportation of sufficient quantities of material to allow the boiler to run without interruption between deliveries needs designing properly.

So you need a fuel store and fuel transport solution to accommodate quite large volumes of material. The quality of material is often very poor and this also requires careful consideration and design.

Rotating Arm Agitator

This is a helical cutter with a sweep-arm that is independently powered from the auger. It operates depending on the amount of fuel inside the fuel store.

- Fuel type

- Wood chips, shavings

- Boiler size

- <1.5MW

- Fuel store volume

- 50-150m3, 10-30T per silo

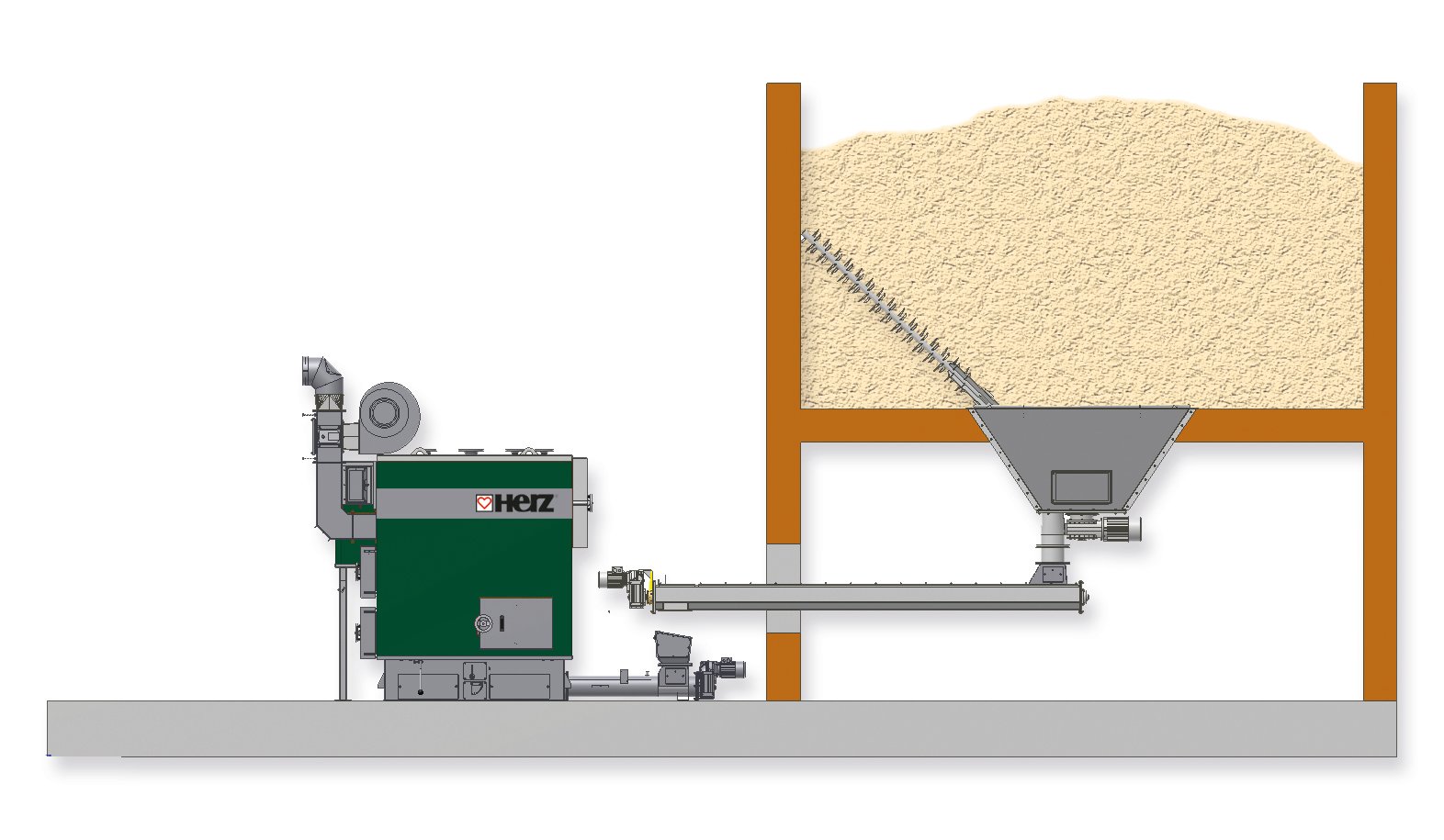

Cone base auger

A free-wheeling spiked auger for fuel extraction out of silos.

- Fuel type

- Wood chips, shavings, sawdust, chipboard, MDF

- Boiler size

- 1-3MW

- Fuel store volume

- 30-200m3, 6-40T per silo

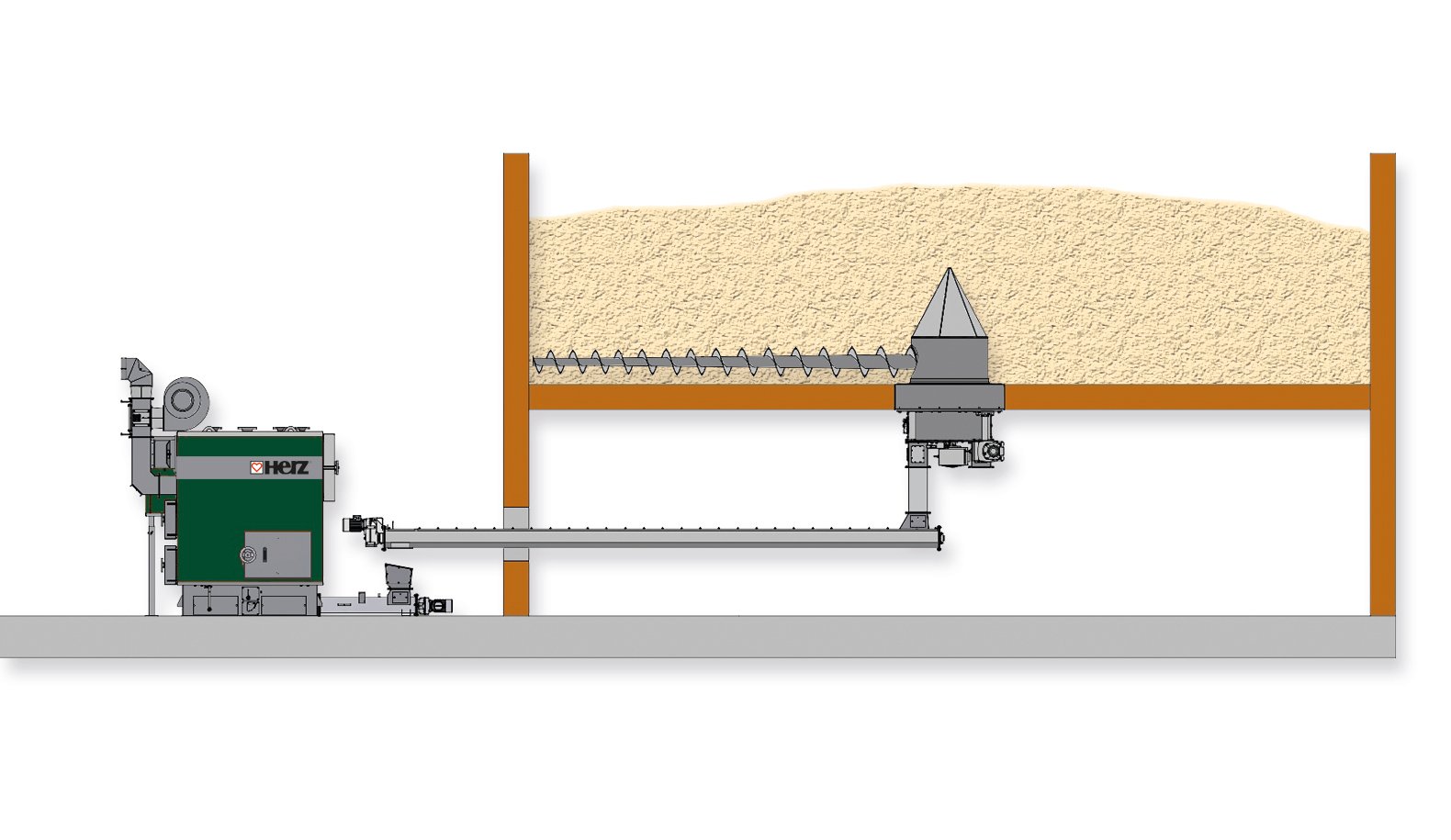

WS Horizontal Sweep Auger

For use with very large diameter (>7m) silos

- Fuel type

- Wood chips

- Boiler size

- 2-5MW

- Fuel store volume

- 100-300m3, 20-60T per silo