Commercial Biomass - Fuel Storage Ideas

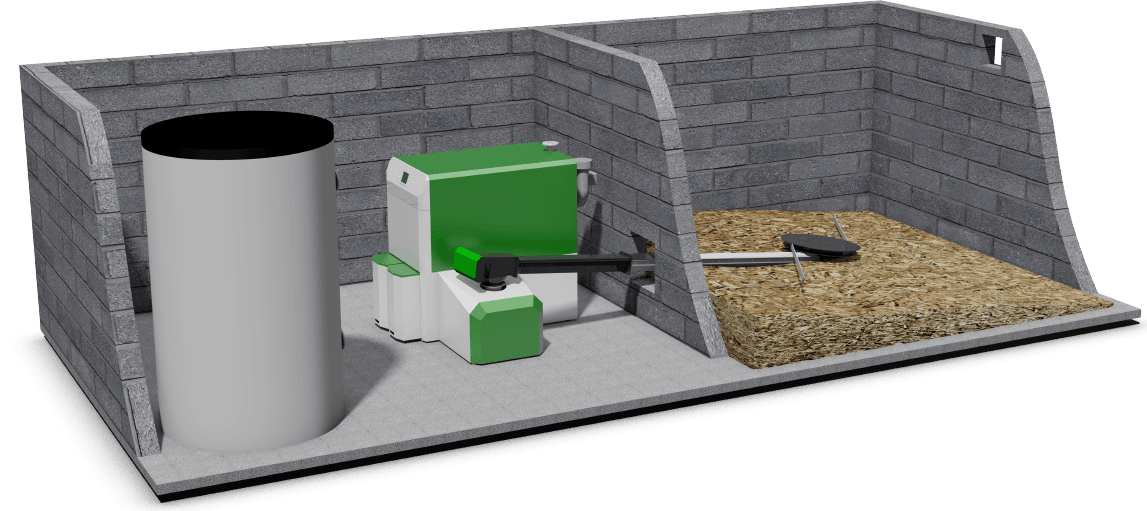

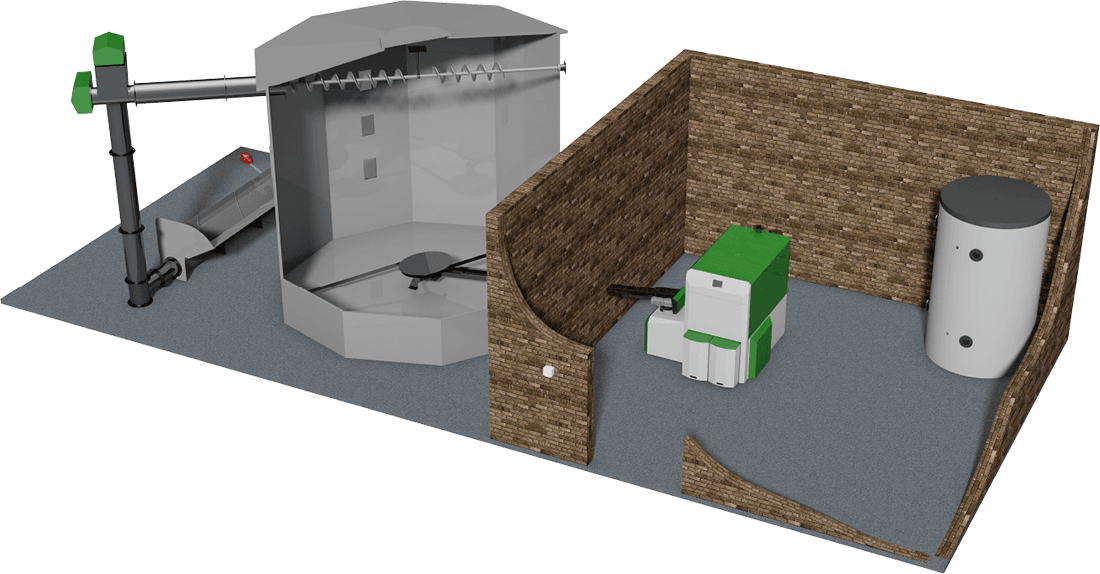

Chip Boiler, Rotary Agitator – Ground Level – Block Built Fuel Store

Installed inside a simple block built, or existing, room for storing wood chips. The rotating springs in the centre scoop the chips towards a single extraction auger which feeds the boiler. Simple, robust and excellent for good quality wood chips

- Fuel type

- Wood chip

- Fuel extraction type

- Rotary agitator, from 3m to 6m diameter

- Fuel store type

- Blockwork, 20-120m3, 5-30T, 3x3m to 6x6m footprint, up to 6m high

- Fuel store location

- On ground level

- Fuel delivery vehicle

- Telehandler or tractor with bucket or blown in

Chip Boiler, Rotary Agitator – Ground Level – Steel Modular Fuel Store

Boiler installed inside a building and the ful store is external constructed from a steel modular frame. Chip can be tipped in using a tractor bucket or blown in directly. The rotating springs in the centre scoop the chips towards a single extraction auger which feeds the boiler. Simple, robust and excellent for good quality wood chips

- Fuel type

- Wood chip

- Fuel extraction type

- Rotary agitator, from 3m to 6m diameter

- Fuel store type

- Steel, 20-100m3, 5-25T, 3x3m to 6x6m footprint, up to 7m high

- Fuel store location

- On ground level

- Fuel delivery vehicle

- Telehandler or tractor with bucket or blown in

Chip Boiler, Rotary Agitator – Ground Level – Steel Silo Fuel Store

Here the rotary agitator is positioned inside a bespoke steel silo. Additional ‘ring’ sections can be added to increase the capacity.

- Fuel type

- Wood chip, medium quality

- Fuel extraction type

- Rotary agitator, from 3m to 6m diameter

- Fuel store type

- Blockwork or steel, 20-120m3, 5-30T, 3x3m to 6x6m footprint, up to 6m high

- Fuel store location

- On ground level

- Fuel delivery vehicle

- Tipper or articulated vahicle, or tractor with loading bucket

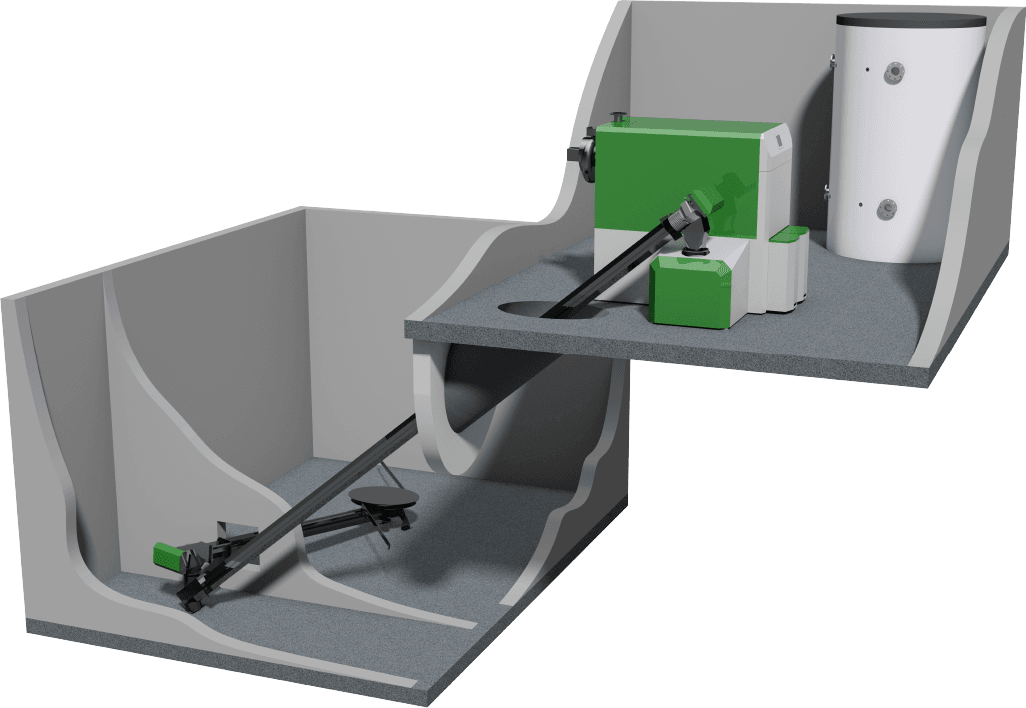

Chip Boiler, Rotary Agitator – Below Ground Level Fuel Store

This design shows a subterranean bunker, built to prevent water ingress and allows excellent access for tipper vehicles and large walking floor vehicles.

Rotary agitators are suited for storage rooms with a footprint of 3x3m up to 6x6m and up to 6m in height.

- Fuel type

- Wood chip, medium quality

- Fuel extraction type

- Rotary agitator, from 3m to 6m diameter

- Fuel store type

- Concrete 20-120m3, 5-30T, 3x3m to 6x6m footprint, up to 6m deep

- Fuel store location

- Below ground level

- Fuel delivery vehicle

- Tipper or articulated with walking floor

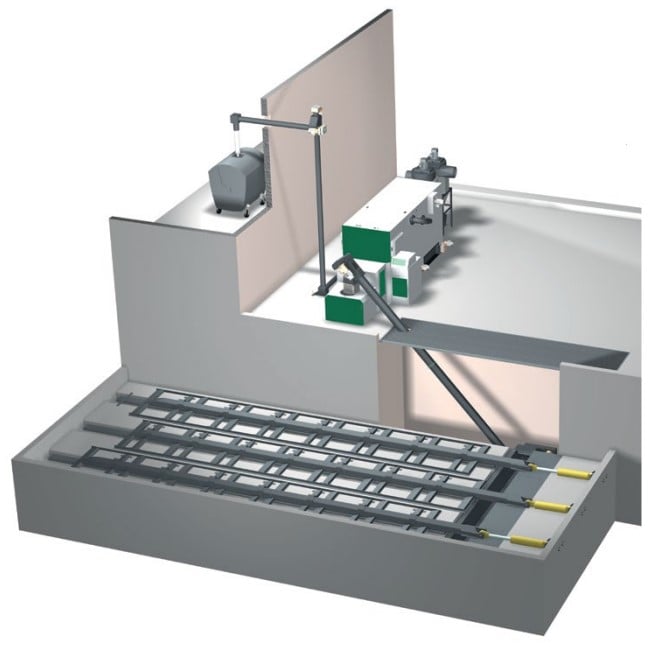

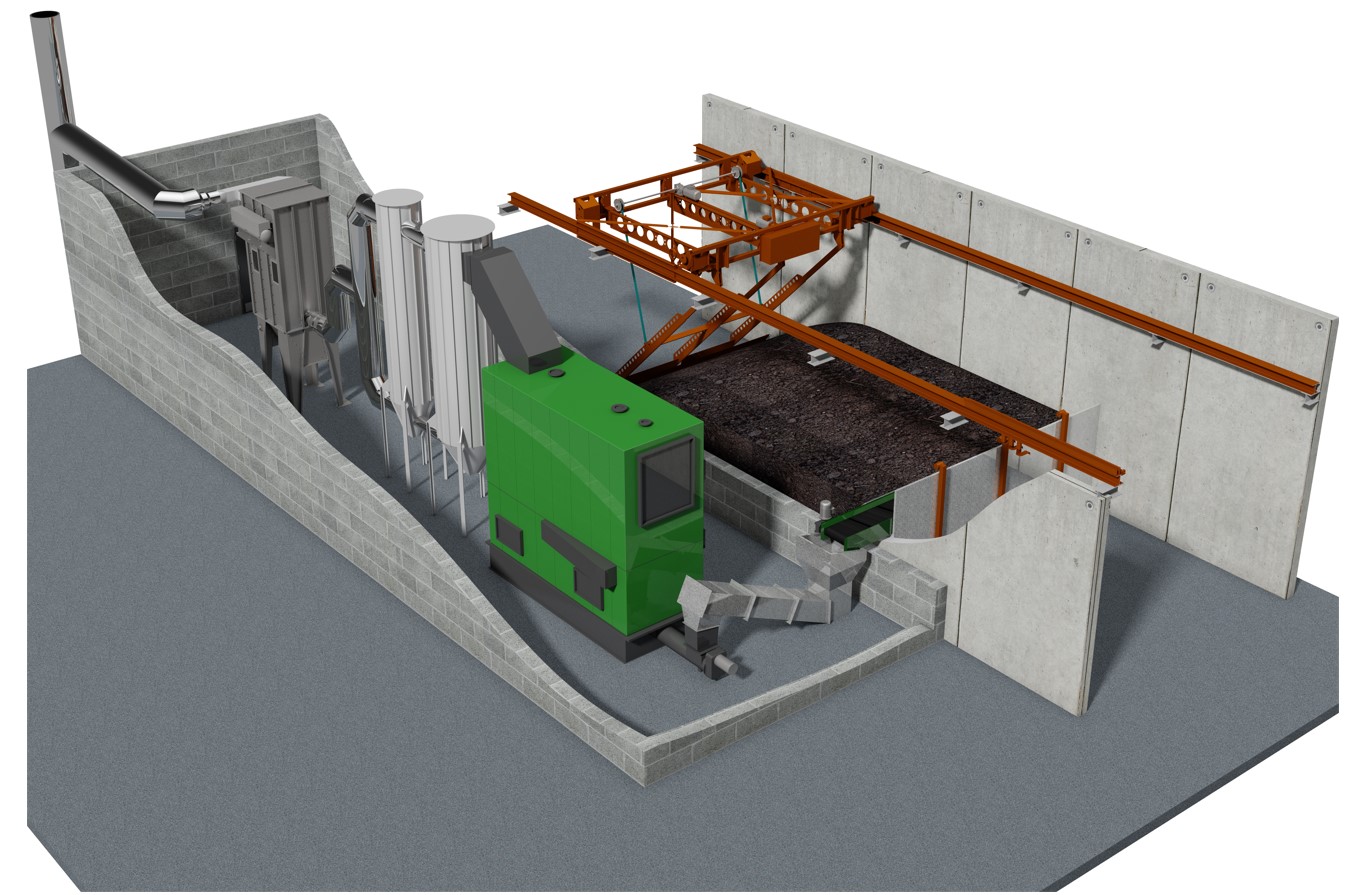

Chip Boiler, Push (Walking) Floor Fuel Store

Push floors are extremely robust and long lasting and can handle very large wood chip pieces. The push rams are hydraulically operated and the whole package is very simple to maintain.

The system automatically loads biomass fuel into a conveyor, from where the material is fed into augers or a chain conveyor which moves the biomass fuel to the boiler as needed.

- Fuel type

- Wood chips, Poor quality, ie high water content and large particle size

- Fuel extraction type

- Hydraulic push ladders, each ladder is 1.8-2.2m wide and from 8m to 12m long

- Fuel store type

- Concrete base and walls. Typically 80-100m3 storage capacity per ladder, typically 2 to 4 ladders side by side

- Fuel store location

- Ground level or below ground

- Fuel delivery vehicle

- Large tippers or articulated with a walking floor offloader. Push floor can be ‘drive on’

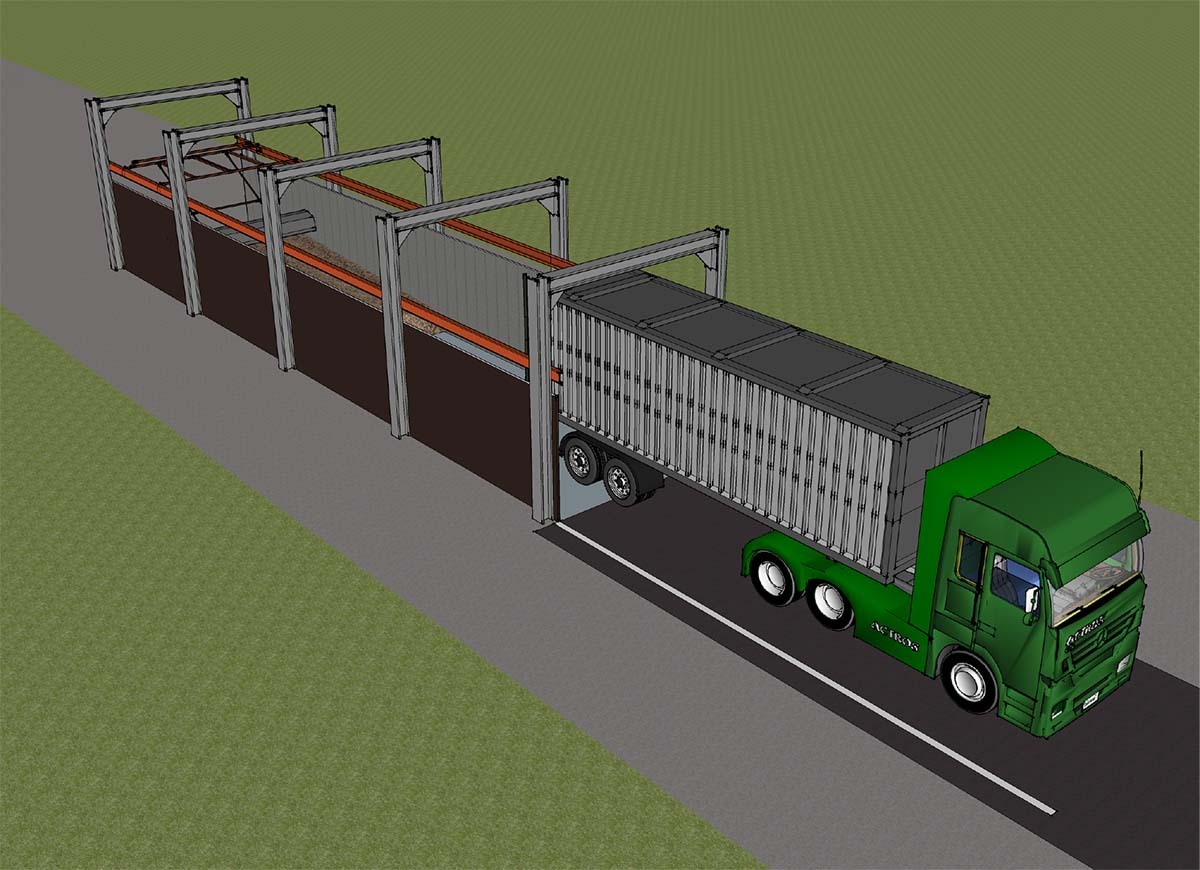

Chip Boiler, Top Loader Fuel Store

This moves on top of the wood chip fuel and scrapes the top layer towards the auger screw/belt conveyor/chain conveyor which transports the chip to the boiler.

This allows for large fuel deliveries from multiple articulated vehicles, cutting down the number of deliveries per annum. It also ensures easy maintenance as the entire mechanism is above the fuel and not buried beneath like all the other options described here, so prior emptying of the fuel store is not necessary.

- Fuel type

- Wood chipsHigh water content and large particle size

- Fuel store type

- Concrete base and wallsTypically 150-400m3 storage capacity per Toploader

- Fuel store location

- Ground level

- Fuel delivery vehicle

- Any type of vehicle but typically large articulated with a walking floor offloader.