Combustion Systems for Industrial Biomass Boilers

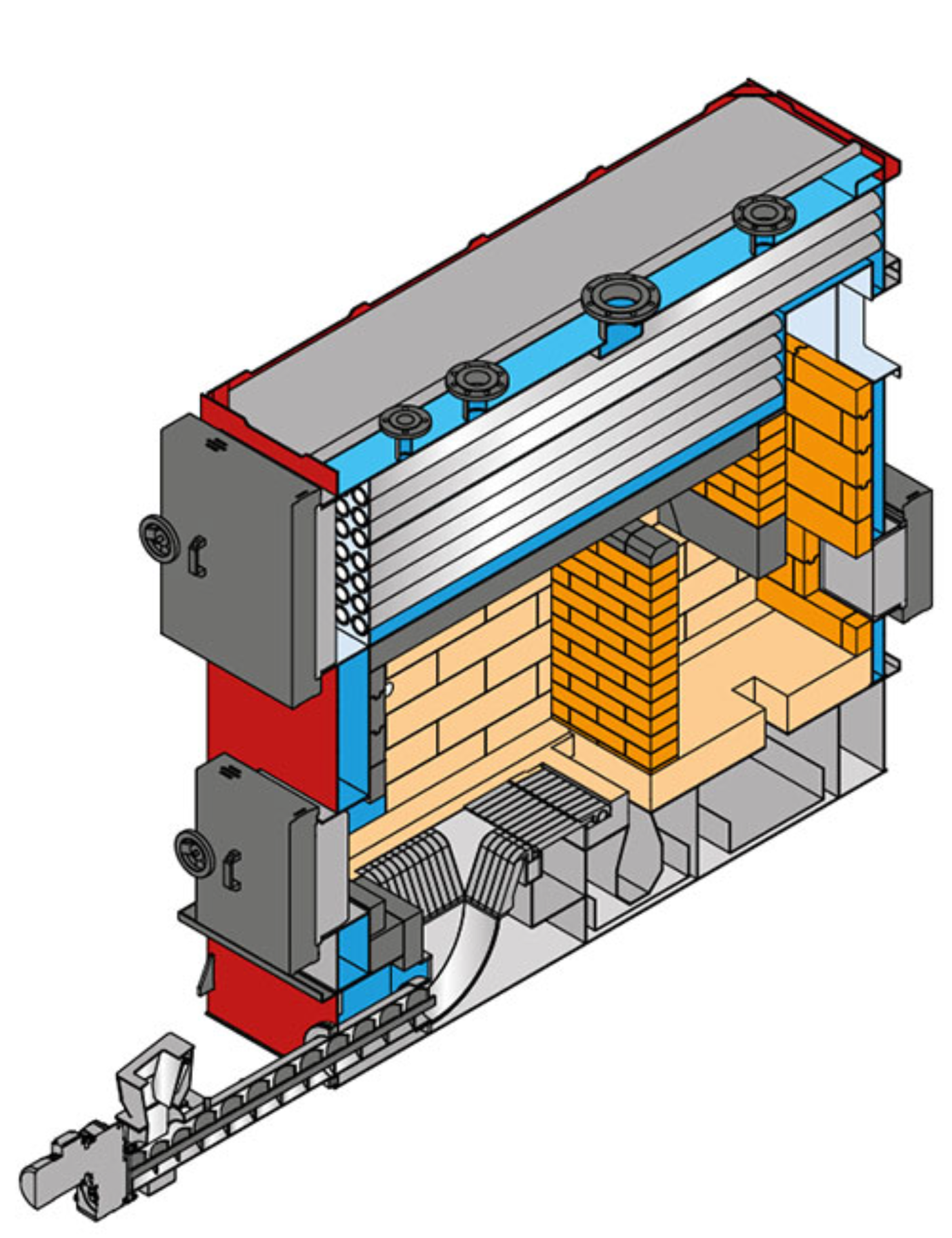

Fixed grate, underfed hearth

Combustion with hearth and a rear grate section with hinged cast steel elements. Ash trays are integrated and there is an optional auto de-ashing with auger.

Completely refractory lined and stoichiometrically designed primary and secondary combustion air zones.

- Max. fuel water content

- Up to M30

- Max. fuel ash content <1,5%

- <1,5%

- Typical Application

- Industrial, public & commercial buildings

- Available

- From 100 kW nominal capacity

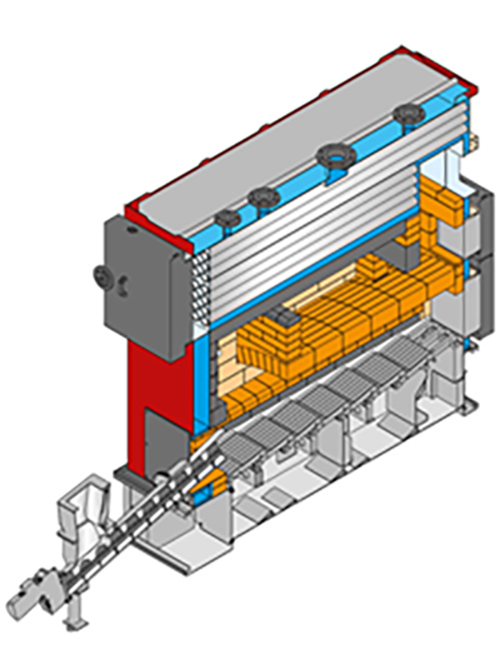

Moving stepped grate for moist fuels

Combustion with hydraulically or electro-mechanically operated stepped grate, for combustion of dry fuels with high ash content.

Fully automatic de-ashing of the combustion unit with ash scraper below grate and ash auger. Completely refractory lined combustion chamber.

Stoichiometrically designed primary and secondary combustion air zones. Alternatively with auger or hydraulic infeed.

- Max. fuel water content

- Up to M40 (up to M50 with air preheater)

- Max. fuel ash content

- <7%

- Typical Application

- Combustion units for industry, district and local heating etc

- Available

- From 300 kW nominal capacity

- Max. fuel water content

- Max. fuel water content Up to M40 (up to M50 with air preheater)

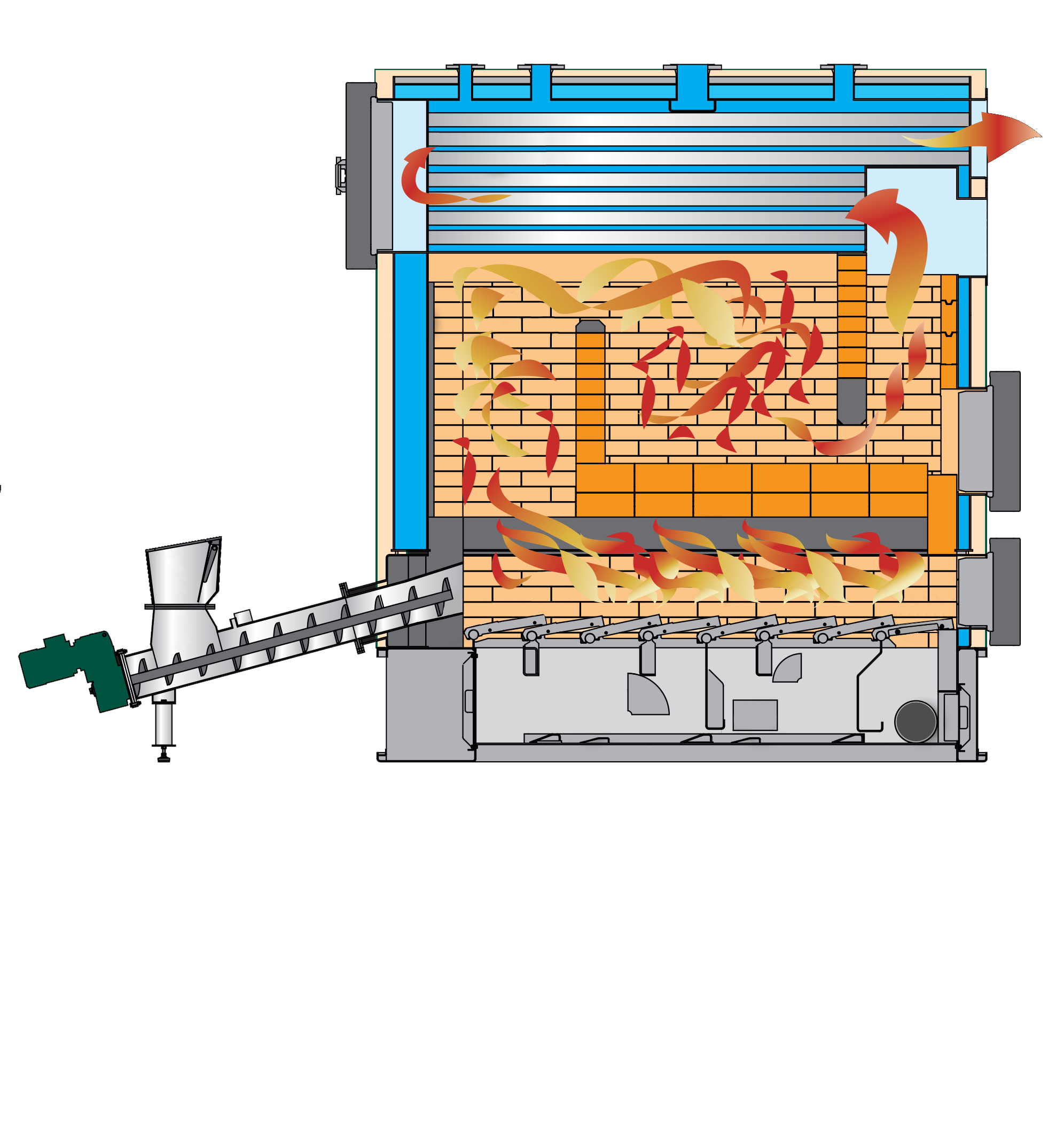

Moving stepped grate for wet fuels

Combustion unit with hydraulically or electro-mechanically operated stepped grate, for combustion of wet materials with high ash content.

Fully automatic de-ashing of the combustion unit with ash scraper below grate and ash auger. Completely refractory lined and Stoichiometrically designed primary and secondary combustion air zones.

Alternatively with auger or hydraulic infeed.

- Max. fuel water content

- Up to M50 (up to M60 with preheater)

- Max. fuel ash content

- <7%

- Typical Application

- Combustion units for industry, district and local heating

- Available

- From 300 kW nominal capacity